Working in a number of sectors and with industry leadings brands, Hub is internationally recognized for its premier printing and folding carton packaging.

Tony DiRico, CEO of HUB:

Adam Melton and Tom Wang, co-founders of GPA:

“We are extremely excited to be part of the GPA Global family. It was important to our family that we found the right partner that wanted to build on our 102 plus years of success and innovation in a sustainable way. We wanted to ensure that our long standing customer relationships would remain intact and importantly that our most cherished assets, our employees, would be part of the next generation of Hub!”

“GPA has always focused on sustainability and environmental considerations are at the heart of the GPA ethos, we’re pleased to be partnering with a company that has made a commitment to sustainability. As part of the GPA Global family, Hub will be a crucial addition to our US domestic offering while bringing that best-in-class manufacturing experience & know-how to achieve the highest possible quality and the most competitive pricing to meet the ever changing needs of global brands.”

Intent on being a company that first and foremost ‘does the right thing’, HUB’s environmental credentials speak for themselves. From designing and building a facility in 1981, which utilized the heat from their manufacturing equipment to self-generate heat for all production areas, to recycling 100% of all their by-products today, Hub has always been about the environment.

Now firmly rooted in our global team, HUB’s wealth of knowledge and expertise has proved invaluable in helping us move into a new chapter of our life.

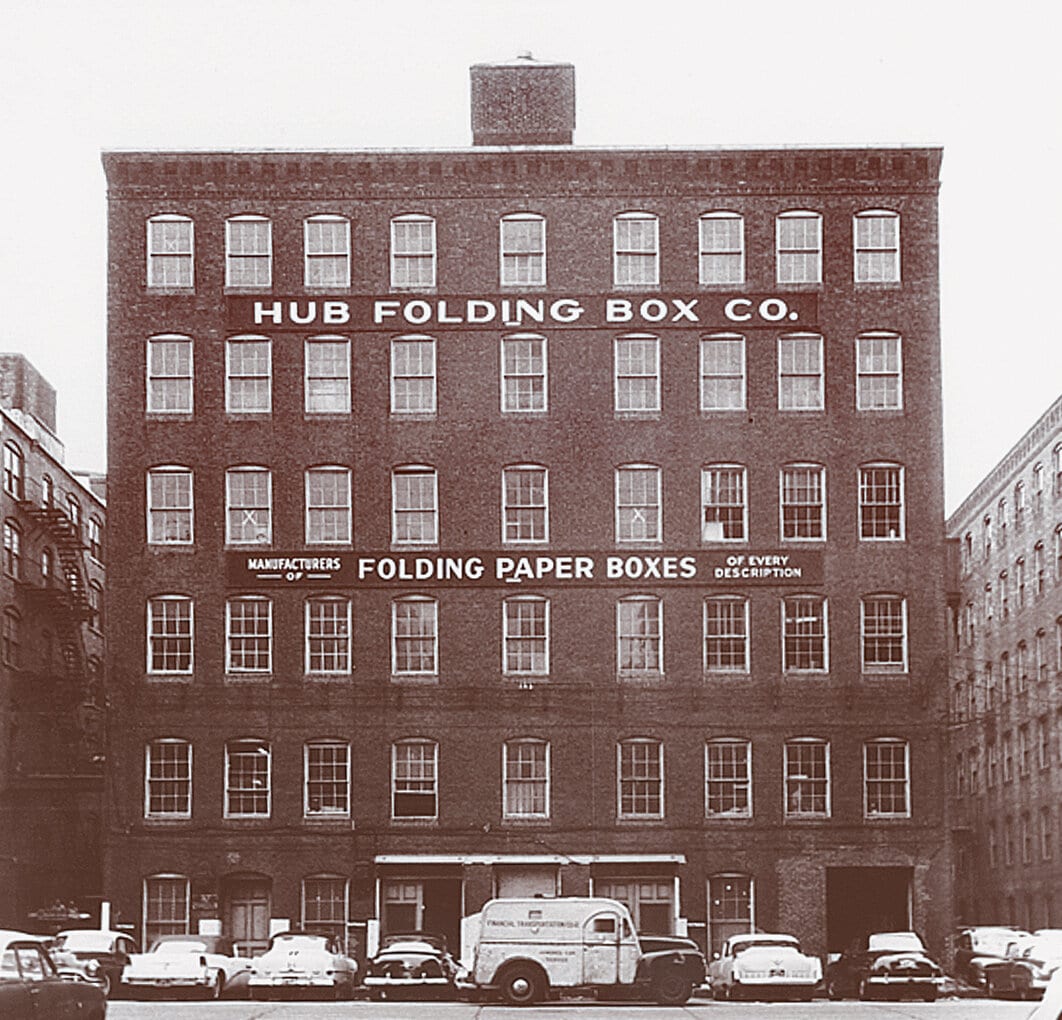

When looking at our group portfolio of best-in-class companies, special mention must be made to the extraordinary and unique legacy of HUB Folding Box, which was first established in 1918. To be able to welcome a company with such a long and prestigious history, not only gives us great pride but also speaks volumes to the vision and continued entrepreneurial ambitions of the family.

With an unwavering drive propelling the company forward, HUB quickly made a name for itself in Massachusetts. Over the course of the 20th century, the company was responsible for ground-breaking innovations; becoming the first folding carton manufacturer to develop and utilize cellophane windows in tomato boxes, permanently transforming the food and bakery industry.

Also, a six-bottle carrier for Orange Crush, which they Patented in 1941, highlighting a few examples of the many achievements Hub has created along the way.

Still part of the DiRico family, today HUB is widely revered for its creativity and innovation in the packaging industry. They specialize in printing and converting graphic-intensive paperboard and plastic folding cartons, contract packaging and fulfillment services, and plastic thermoforming and design – all while keeping sustainability at the heart of their operations.

Update 2022

To keep HUB’s un-faltering standards and maintain their position as one of the best in the business, this year we set out to boost their manufacturing capabilities. HUB’s operation warranted industry-leading manufacturing capabilities. So that’s exactly what we delivered.

Now with a host of new state-of-the-art machinery throughout both our east and west coast manufacturing sites, HUB’s capabilities have grown exponentially. With machinery such as The Rapida 145 – with production speeds of up to 18,000 sph, we can now output almost 10 million A4 pages a day, handle sheet sizes of up to 1,060 x 1,450 mm, and change jobs at a fraction of the time of standard equipment.

Hub Folding Box Company is honored to have been the recipient of many prestigious awards within the printing industry during the past few decades, including:

We’re in the business of creating brand elevating, award-winning packaging for your product